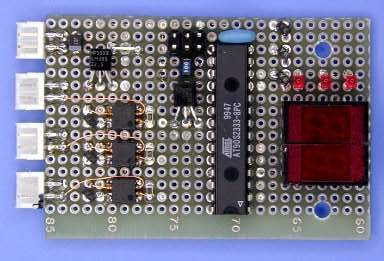

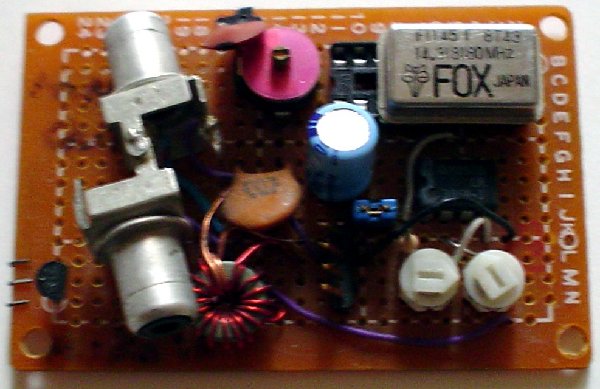

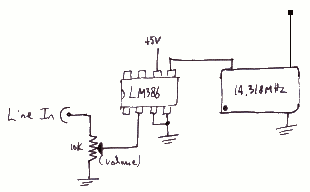

Till Harbaum has build a WLAN system, SPI2CF, which is small, simple and cheap. Using SPI2CF WLAN System you can leave much of the AVR functionality for other use and allowing fast and reliable WLAN data transfers. The final design was based on a prism chipset based compact flash WLAN card which is connected to the AVR CPU using a programmable logic chip (CPLD) made by Xilinx. Since the CF card is attached to the AVR using the SPI interface the entire system is named the SPI2CF project. You can get the complete compact flash specification from the Compact Flash Association.

Till Harbaum has build a WLAN system, SPI2CF, which is small, simple and cheap. Using SPI2CF WLAN System you can leave much of the AVR functionality for other use and allowing fast and reliable WLAN data transfers. The final design was based on a prism chipset based compact flash WLAN card which is connected to the AVR CPU using a programmable logic chip (CPLD) made by Xilinx. Since the CF card is attached to the AVR using the SPI interface the entire system is named the SPI2CF project. You can get the complete compact flash specification from the Compact Flash Association.Download : schematic, verilog source code, uip port

tag : AVR, Project, WLAN, Data Transfer, Wireless Project, Microcontroller Design (src)